直缝钢管管道防腐的办法

Anti-corrosion Measures for Straight Seam Steel Pipeline

外壁防腐涂层:管道外壁涂层资料品种和运用条件。

Anti-corrosive coatings on the outer wall of pipelines: materials and operating conditions of coatings on the outer wall of pipelines.

内壁防腐涂层:爲了避免管内腐蚀、降低摩擦阻力、进步输量而涂于管子内壁的薄膜。常用的涂料有胺固化环氧树脂和聚酰胺环氧树脂,涂层厚度爲 0.038~0.2毫米。爲保证涂层与管壁粘结结实,必需对管内壁停止外表处置。70年代以来趋向于管内、外壁涂层选用相反的资料,以便管内、外壁的涂敷同时停止。

Inner wall anticorrosive coating: To avoid corrosion in the pipe, reduce friction resistance, improve the flow rate and coat the film on the inner wall of the pipe. The common coatings are amine cured epoxy resin and polyamide epoxy resin. The thickness of coatings is 0.038-0.2mm. In order to ensure the bonding between the coating and the pipe wall, it is necessary to stop the external disposal of the pipe wall. Since the 1970s, it has tended to choose the opposite material for inner and outer wall coatings, so that both inner and outer wall coatings can be stopped at the same time.

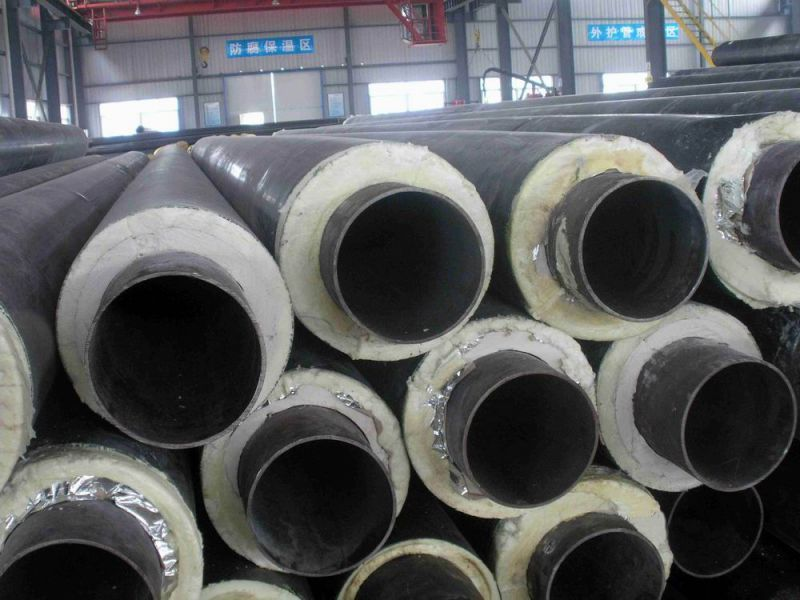

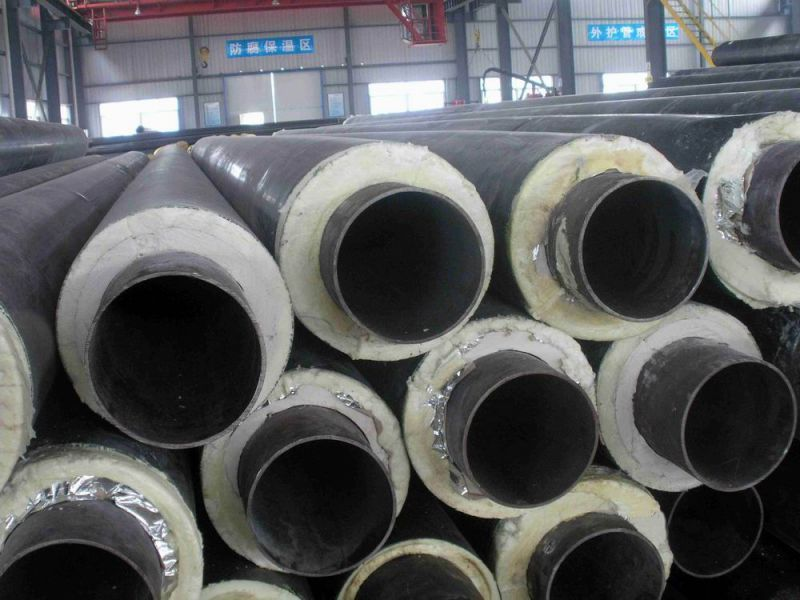

防腐保温涂层:在中、小口径的热输原油或燃料油的管道上,爲了增加管道向土壤散热,在管道内部加上保平和防腐的复合层。常用的保温资料是硬质聚氨脂泡沫塑料,适用温度爲-185~95℃。这种资料质地坚实,爲进步其强度,在隔热层里面加敷一层高密度聚乙烯层,构成复合资料构造,以避免地下水渗入保温层内。

Anti-corrosion and thermal insulation coating: In order to increase the heat dissipation of pipeline to soil, a compound layer of flatness and anti-corrosion is added to the pipeline on medium and small diameter pipelines for heat transportation of crude oil or fuel oil. The commonly used heat preservation material is rigid polyurethane foam, and the applicable temperature is - 185 - 95 C. In order to improve its strength, a layer of high density polyethylene (HDPE) is added to the thermal insulation layer to form a composite data structure to avoid groundwater infiltrating into the thermal insulation layer.

电法维护

Electrical maintenance

改动金属于四周介质的电极电位,使金属免受腐蚀的办法。长输管道电法维护仅指阴极维护和电蚀避免法。

Change the electrode potential of the metal absolutely in the surrounding medium, so that the metal is not corroded. Electrical maintenance of long distance pipeline only refers to cathode maintenance and corrosion avoidance.

阴极维护:将被维护金属极化成阴极来避免金属腐蚀的办法。这种办法用于船舶防腐已有 150多年的历史;1928年一次用于管道,是将金属腐蚀电池中阴极不受腐蚀而阳极受腐蚀的原理使用于金属防腐技术上。应用外施电流迫使电解液中被维护金属外表全部阴极极化,则腐蚀就不会发作。判别管道能否到达阴极维护的目标有两项。一是小维护电位,它是金属在电解液中阴极极化到腐蚀进程中止时的电位;其值与环境等要素有关,常用的数值爲- 850毫伏(于铜-硫酸铜参比电极测定,下同)。二是大维护电位,即被维护金属外表允许到达的高电位值。当阴极极化过强,管道外表与涂层间会析出氢气,而使涂层发生阴极剥离,所以必需控制汇流点电位在允许范围内,以使涂层免遭毁坏。此值与涂层性质有关,普通取-1.20-2.0伏间。完成地下管道阴极维护有外加电流法和牺牲阳极法两种。

Cathodic Maintenance: Polarization of the maintained metal into a cathode to avoid metal corrosion. This method has been used for anti-corrosion of ships for more than 150 years. It was first used in pipelines in 1928. The principle that the cathode of metal corroded batteries is not corroded while the anode is corroded was applied to metal anti-corrosion technology. If the applied current is applied to force the cathodic polarization of the surface of the maintained metal in the electrolyte, the corrosion will not occur. There are two criteria to determine whether the pipeline can reach the goal of cathode maintenance. The first is the minimum maintenance potential, which is the potential of metal from cathodic polarization in electrolyte to the end of corrosion process. Its value is related to environment and other factors. The commonly used value is - 850 mV (absolutely determined by copper-copper sulfate reference electrode, the same below). The second is the maximum maintenance potential, which is the maximum potential allowed to be reached by the surface of the maintained metal. When the cathodic polarization is too strong, hydrogen will precipitate between the surface of the pipeline and the coating, which will lead to the cathodic stripping of the coating. Therefore, it is necessary to control the potential of the confluence point within the allowable range in order to prevent the coating from being destroyed. This value is related to the properties of the coating. It is usually taken between -1.20 and -2.0 volts. There are two methods for cathode maintenance of underground pipelines, i. e. external current method and sacrificial anode method.

牺牲阳极法是采用比被维护金属电极电位更负的金属与被维护金属衔接,两者在电解液中构成原电池。电位较负的金属(如镁、锌、铝及其合金)成爲阳极,在输入电流的进程中逐步损耗掉,被维护的管道金属成爲阴极而免遭腐蚀,所以称电位较负的金属爲牺牲阳极。其接线如图4。 地下管道采用牺牲阳极维护,其决议要素是阳极发作电流、阳极数量和维护长度等。当阳种确定后,影响上述参数的是阳极接地电阻和与该阳极维护管段区间的漏泄电阻。前者取决于土壤电阻率,后者取决于管道涂层电阻和涂层的施工质量。牺牲阳极运用寿命与分量有关,视需求可用几年几十年。牺牲阳有投资省、管理简便、不需求外电源、避免搅扰腐蚀效果好等优点,所以在地下金属管道防腐中失掉普遍使用。

The sacrificial anode method is to connect the metal with the maintained metal, which is more negative than the potential of the maintained metal electrode. Both of them constitute the primary battery in the electrolyte. Metals with negative potential (such as magnesium, zinc, aluminium and their alloys) become anodes, which are gradually depleted in the process of input current, and the maintained pipeline metals become cathodes to avoid corrosion, so the metal with negative potential is called sacrificial anode. Its wiring is shown in Figure 4. Underground pipelines are maintained with sacrificial anodes, whose key factors are the current of anode onset, the number of anodes and the length of maintenance. When the type of anode is determined, the above parameters are affected by the grounding resistance of the anode and the leakage resistance of the maintenance section of the anode. The former depends on the soil resistivity, and the latter depends on the resistance of pipeline coating and the construction quality of coating. The service life of sacrificial anode is related to its component, and it can be used for years to decades depending on the demand. Sacrifice anode has the advantages of low investment, simple management, no need for external power supply, good effect of avoiding disturbance and corrosion, so it is widely used in underground metal pipeline corrosion protection.

电蚀避免法:一是在杂散电流源有关设备上采取措施,使漏泄电流减小到低限制;二是在敷设管道时尽量避开杂散电流地域,或进步被搅扰管段绝缘防腐层质量,采用屏蔽、加装绝缘法兰等措施;三是对搅扰管道作排流维护,行将杂散电流从被搅扰管道排回发生漏泄电流的电网中,以消弭杂散电流对管道的腐蚀。依据使用范围和排流设备的不异性能,分间接排流、极性排流、强迫排流三种。对交流搅扰电压的防护,不少国度都制定有技术规则,次要是采用平安间隔和管道泄流两类办法使管道免遭损害。

Corrosion avoidance method: first, take measures to reduce leakage current to the minimum limit on stray current source related equipment; second, avoid stray current area as far as possible when laying pipelines, or improve the quality of insulating anticorrosive layer of disturbed pipeline section, adopt shielding, installing insulating flange and other measures; third, make drainage maintenance for disturbed pipelines. The stray current will be discharged from the disturbed pipeline back to the leakage current grid to eliminate the corrosion of the stray current to the pipeline. According to the scope of use and the non-uniform performance of drainage equipment, there are three types: indirect drainage, polar drainage and forced drainage. For the protection of AC disturbance voltage, many countries have formulated technical rules. Secondly, safe interval and pipeline discharge are used to protect pipelines from damage.

In summary, all the above-mentioned Shandong Hipper Pipe Technology Development Co., Ltd. provides, want to know more about the black jacket straight-seam steel pipe, welcome to pay attention to our website: http://www.sdhpgy.com Thank you for your support!